Description

Application

Self acting valve that prevents in reverse f1ow of operating medium designed for water, water steam and other operat- ing media used in power engineering and chemical industries, for normal, tropical and explosive environments.

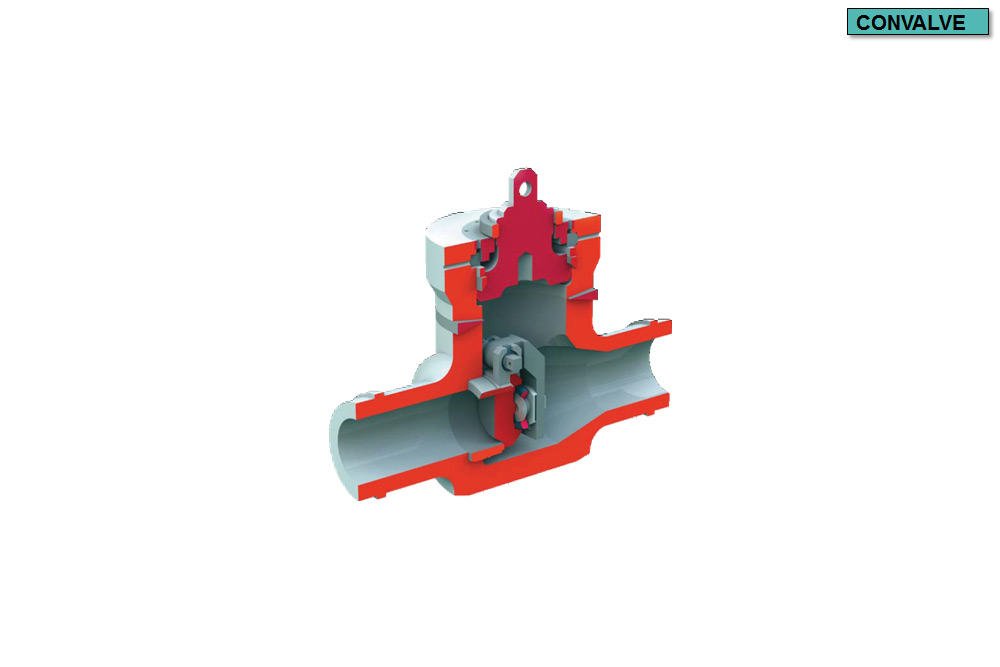

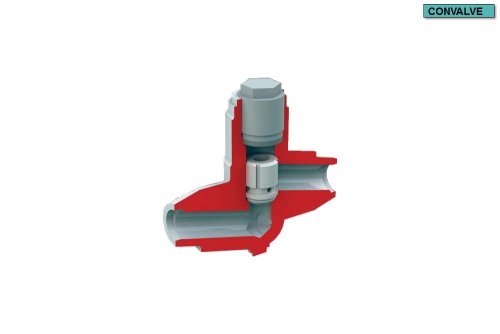

Technical description

The body is formed by a die or smith forging. The seat is pressed in the body and welded with a sealing weld. The sealing surface of the seat and plate is welded using a hard welding-on alloy. The sealing ring of the pressure seal bonnet is made of expanded graphite. Operating is automatic.

Testing

The valves are tested with water (upon client request even by steam) for strength, impermeability, and tightness according to operating parameters and body material. Minimum strength testing pressure is 1,5 fold of PN. The strength welds are tested by X-ray scanning.

Installation

The valves are installed in horizontal piping with the pressure seal bonnet facing upwards, with the direction of f1ow aimed under the plate.

Connection

Flanged and butt-welded as per CSN, DIN, ANSI, GOST standards.