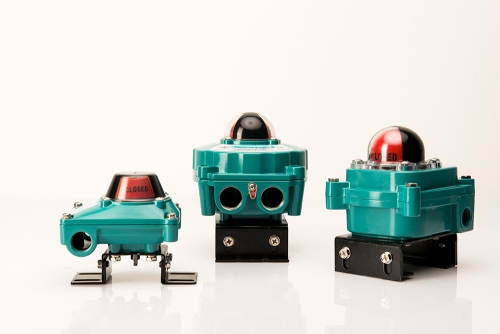

Description

Air actuators in general are known in the industry to be very rugged, reliable and durable. Convalve heavy duty quarter turn air actuators are prelubricated and tested to a minimum one million operations. Actuators are available in double acting and spring return models. They meets international ISO 5211 standards for easy valve mounting and replacement. Position confirmation switches and valve positioners can be easily mounted to the actuator with the standard VDI/VDE-3845 top mounting pad. Rotation adjustment +/- 5% in both open and closed position. Visual position indicator will monitor the open and closed position.

Features

- Rack and pinion quarter turn (90°) rotation

- Double acting and spring return models

- Prelubricated and tested to minimum 1 million operations

- Direct valve mounting per ISO5211

- Visual valve position indicator

- Extruded aluminum body with 50 micron hard anodizing

- Corrosion resistance – 500 hour minimum salt spray test

- Spring return models use pre compressed spring cartridges

- Female double square output drive

- Namur mounting pad for direct mount solenoid valves

- Standard VDI/VDE 3845 mounting for top mount accessories

Applications

Convalve air actuators are typically used to operate quarter turn ball valves, butterfly valves and plug valves. They can also be applied virtually anywhere a 90 degree rotation is required such as dampers. Quick and easy to install with standard ISO5211/DIN 3337 mounting dimensions and a double square female output drive. The operating temperature range of the actuator is –20 to 80℃.

Operation

Double acting actuators require air pressure to open and air pressure to close. Spring return actuators require air pressure to open and utilize springs to close for failsafe operation. Typically 4-way pilot valves are used to control a double acting actuator and 3-way pilot valves for spring return models. Pilot air should be filtered, dry or lubricated. Output drive rotates counter-clockwise to open when viewed from top of actuator.

Options

- Direct mount solenoid valves

- Monitor/Position confirmation limit switches

- Electro-Pneumatic positioner 4-20m input

- Pneumatic positioners 3-15 PSI input

Construction

| Body | ASTM 6063 extruded aluminium, 50 micron anodizing |

| End Covers | ASTM B179 die-cast aluminium, 60-80 micron polyester coating |

| Drive Shaft | Carbon steel, 20 micron nickel plated |

| Position Indicator | Glass filled polyamide |

| Seals | NBR |

| Springs (spring return model) | Pre-compressed cartridges, 60-80 micron polyester coating |

| Pistons | ASTM B179 die-casted aluminium alloy 15 micron anodizing |

| Pilot Air Connection | 1/4” NPT plus standard Namur solenoid mounting pad |

| Fasteners | 304 stainless steel |