Description

Application

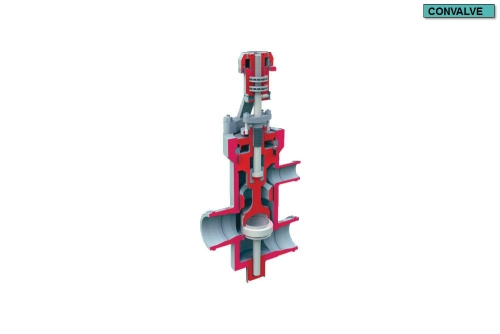

Multi-stage control valve with a linear characteristic designed for water, water steam, gases and other operational media used in power engineering and chemical industries, for standard, tropical and explosive environments. The operating parameters required so far are listed in the table. The valves allow reducing pressure gradient in liquids (i.e. the pressure difference between the inlet and outlet sides) within the range from 5,1 up to 20 MPa and the expansion ratio (i.e. the ratio of the outlet pressure with respect to inlet one) in vapours and gases within the range from 0,7 up to 0,2 MPa.

Technical description

The body is formed by a die forging and a cast yoke that are linked mutually using two pins. The seat in the body and throt- tling areas of the expansion chambers are welded-on using a hard surfacing alloy. The plug with the stem is made as single piece from chrome-plated steel, hardened, provided with series of wedged grooves creating the throttling system itself. The seal is made of asbestos-free material. Operating is carried out either with a hand wheel or with an electric linear actuator.

Operation

Operation is carried out with a hand wheel or with an electric actuator. The valves with the hand wheel can be provided with a locking system.

Sketches for orientation only, exact dimensions of given points can be specified upon request.

Sketches for orientation only, exact dimensions of given points can be specified upon request.

Testing

The valves are tested with water (upon client request even by steam) for strength, impermeability, operation ability and tightness. Minimum strength testing pressure is 1,5 fold of PN.

Installation

The valves can be installed in any position with the direction of flow through the inlet side nozzle above the plug. The control with the electric actuator when the electric motor axis should be horizontal represents an exception. In order to allow proper control function, it is not advisable to install shaped pipe com- ponents, transitions, valves, etc. immediately before and behind the valve. The valves can be mounted by the cylindrical surface created on the bottom outlet nozzle.

Connection

Butt-welded as per CSN, DIN, ANSI, GOST standards.

The valves can be supplied with electric actuators of the manufacturers ZPA Pečky, Regada, AUMA, Rotork, Schiebel and others.

Operating parameters

Multi-stage control valve G30, DN 25/50 – 100/100, PN 400