Description

Application

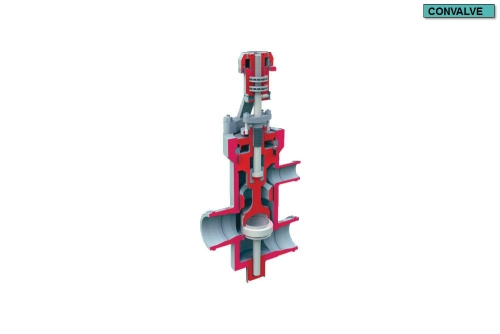

Check valve that is used to automate and to operate the power engineering block, in particular in the event of a failure of the piping system in the high-pressure heater and upon level rising above the permitted height.

Technical description

The body is a smith forging with butt-welded nozzles, yoke made from steel, welded. The sealing surface of the seat and the plug disc are butt-welded using a stainless steel electrode. The stem seal and the sealing ring of the pressure seal bonnet are made from expanded graphite.

Operation

Control with electric actuator, hand wheel.

Sketches for orientation only, exact dimensions of given points can be specified upon request.

Testing

The valves are tested by water for strength and impermeability by application of pressure min. 1,5 Pp, for operational capability and leak using Pp pressure. The strength welds are tested by X- ray scanning.

Installation

The valves are installed in horizontal piping only with the con- trols facing upwards, according to the provided diagram and the dimensional sketch.

Connection

Butt-welded as per CSN, DIN, EN, ANSI, GOST standards.

The valves can be supplied with electric actuators of the manufacturers ZPA Pečky, Regada, AUMA, Rotork, Schiebel and others.